Winter is Coming

In the construction industry, we often think that winter weather conditions are the worst for earthwork operations. Although this may be true, we know from experience that poor weather conditions can strike at any time, often wreaking havoc on construction schedules. When natural drying from hot summer temperatures, warm winds, and time are not possible, we must look to alternatives to stabilize subgrades soils to deliver projects on time. The technique we will discuss in this article is chemical stabilization. Most people in our industry are aware of chemical stabilization using Portland cement and Quicklime, but may not be familiar with another product—Calciment®.

Calciment® has been around since 1994 and can be best described as a hybrid between quicklime and cement providing heat generated through exothermic reactions as well as cementitious properties.

Geo-Hydro was recently given the opportunity to experiment with Calciment® in our laboratory on soils representative of metro Atlanta. We amended these soils with varying amounts of Calciment® to show how the product would affect moisture, physical properties, compressive strength, and subgrade strength (CBR).

Geo-Hydro was recently given the opportunity to experiment with Calciment® in our laboratory on soils representative of metro Atlanta. We amended these soils with varying amounts of Calciment® to show how the product would affect moisture, physical properties, compressive strength, and subgrade strength (CBR).

As previously stated, the benefits of Calciment® fall somewhere between those of quicklime and cement. Our experiences have shown that Quicklime provides 2% dry-back for every 1% of quicklime but has very little strength gain. Alternatively, Portland cement has been shown to provide minimal drying capabilities (1% dry-back for every 1% of cement) but has potential for very high strength gain. We observed somewhere between 1 to 2% moisture loss for every 1% of Calciment®.

Chemically, this makes sense because of the amount of calcium oxide (CaO) available in each product. The amount of calcium oxide available in each is typically less than 5% in cement, about 40% in Calciment®, and greater than 90% for quicklime. Calcium oxide, when exposed to water, forms calcium hydroxide. This reaction generates a lot of heat, therefore “drying” the soils.

Regarding compressive strength, our laboratory tests have shown that soils amended with 6% Calciment® can achieve strengths of about 200 psi at 7 days. In most cases, a strength of 200 psi is adequate for stabilizing slab subgrades and even some light duty pavement subgrades. * A slight change was noted in the soils’ physical properties with 6% amendment.

Regarding compressive strength, our laboratory tests have shown that soils amended with 6% Calciment® can achieve strengths of about 200 psi at 7 days. In most cases, a strength of 200 psi is adequate for stabilizing slab subgrades and even some light duty pavement subgrades. * A slight change was noted in the soils’ physical properties with 6% amendment.

Remember, higher compressive strengths are not always better. High compressive strengths (over 500 psi) will typically lead to increased shrinkage cracks which, over time, will reflect through the asphalt.

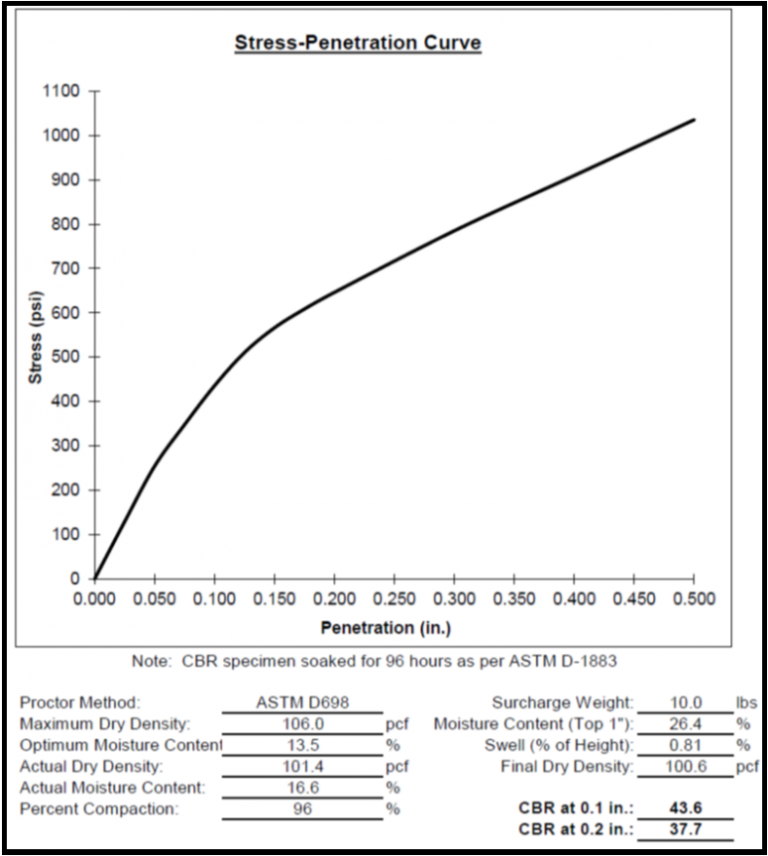

For CBR testing, our results show CBR values increased from 10.4 to 43.6 with a 6 percent amendment rate. In general, an increase in a soil’s CBR will usually allow for the reduction of graded aggregate base and/or asphaltic concrete thicknesses supporting the same traffic.

Based on our past experiences and our recent lab testing, it is our opinion that Calciment® is a viable alternative to Quicklime and Portland cement for stabilizing or improving building and pavement subgrades. When considering any stabilization approach, a qualified geotechnical firm should be engaged to work with owners and contractors to explore all the tools in the toolbox!