Unconventional Fill Materials

In some instances, either as part of design or during construction, special circumstances require the use of fill materials other than traditional structural fill soil. In most cases, performance requirements, weight (load) restrictions, or both dictate the need for special or unconventional fill materials. Common situations requiring fill or backfill materials other than soil include construction of embankments on weak (compressible) underlying soils, the need to reduce loading on retaining walls (new or existing), the need for better performance from backfill materials (higher angle of internal friction), special drainage requirements, or combinations of requirements that cannot be satisfied using conventional structural fill soil.

Alternative materials for use as fill and backfill are numerous, and each has advantages and disadvantages to consider. Invariably, there are additional costs associated with the use of unconventional materials that involve the actual cost of the material, special installation equipment and procedures, special environmental considerations, and time.

The following is a list of some of the many alternative materials that may be available for use as fill and backfill to reduce weight (loading) or improve performance:

- Metallic chips

- Blast furnace slag

- Foamed glass aggregate

- Tire chips

- Steel slag

- Granulated slag

- Sand-biochar mix

- Expanded polystyrene blocks

- Foamed grout

- Expanded shale lightweight aggregate

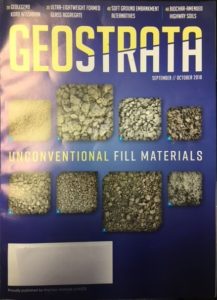

For additional information, the September/October 2018 issue of Geostrata[1] is dedicated to unconventional fill materials with emphasis on Ultra-lightweight Foamed Glass Aggregate, Expanded Polystyrene Blocks (EPS), and Bio-Char Amended Soils.

[1] Geostrata – September/October 2018 (Issue 5 – Volume 22) – Geo-Institute of the American Society of Civil Engineers (ASCE)