Modulus of Subgrade Reaction

Modulus of Subgrade Reaction: What is it? The modulus of subgrade reaction (k) is primarily a mathematical expedient. Essentially, it is an attempt to reduce the behavior of soil subjected to loading to an equivalent, and convenient, “spring constant”. However, one thing (k) is not is a fundamental soil property. The same subgrade conditions and subsurface profile will yield drastically different values of (k) depending on many factors. It is often misunderstood and at times misused.

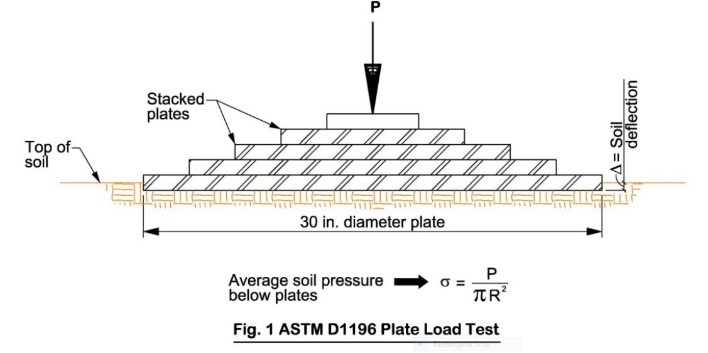

Mathematically, (k) is the applied pressure over a specific area divided by the corresponding deformation (pressure/deflection). The most common expression used to denote (k) is pci. Is that pounds per cubic inch? No. The expression represents pound per square inch per inch of deformation; hence the shortened handle pci. And yes, there is an ASTM Standard to test the modulus of subgrade reaction (ASTM D1196 - Standard Test Method for Nonrepetitive Static Plate Load Tests of Soils and Flexible Pavement Components, for Use in Evaluation and Design of Airport and Highway Pavements).

The modulus of subgrade reaction has been traditionally used in pavement design as a representation of the stiffness of the subgrade soils under short duration, transient loading. With some judgment, (k) values obtained from field testing can be used for pavement design purposes. The magnitude of (k) typically ranges from about 100 to 250 pci, sometimes higher, depending on the subgrade materials and conditions. Additionally, the modulus of subgrade reaction used for design (effective modulus of subgrade reaction) can be enhanced by using a crushed stone course (untreated or cemented).

In contrast, when used as an equivalent spring constant to facilitate the design of mat foundations, or for design/evaluation of floors subjected to semi-permanent or permanent gravity loads (storage racks, line loads, staging of materials, random and heavy floor loads), the same subgrade and subsurface profile will yield drastically different modulus of subgrade reaction values, typically on the order of 25 to 40 percent of the short-term or plate load test value.

Take Away Points

- The modulus of subgrade reaction is influenced by many factors including the elastic properties of the soil, loading intensity, size of the loaded area, and the stiffness of the slab or pavement structure. It is not an intrinsic soil property.

- Your geotechnical consultant needs information to provide the correct modulus of subgrade reaction for use in design. It is important to know the type and magnitude of loading (vehicular traffic, rack storage, area loading, column loads, etc.). The number, size and distribution of loaded slab areas and the duration of the loads. And last, but not least, the tolerance or sensitivity of equipment and operations as they relate to settlement or sloping of the floor and even minor cracking.

- It is important that the design team, including the owner, architect, structural engineer and geotechnical engineer communicate regarding floor loading conditions and performance expectations. Communication will reduce confusion and delays, and improve construction quality and performance.

- Call Geo-Hydro. We can help.